Piping Stress Analysis & Engineering Services

Our services include comprehensive analysis and evaluation of your piping system as per 𝗔𝗦𝗠𝗘 𝗕𝟯𝟭.𝟭 𝗮𝗻𝗱 𝗕𝟯𝟭.𝟯 𝘀𝘁𝗮𝗻𝗱𝗮𝗿𝗱𝘀., identifying potential issues and risks, and recommending appropriate solutions to ensure its integrity and longevity.

Contact Us Today! To learn more about our piping stress analysis services and how we can help you.

Our Services

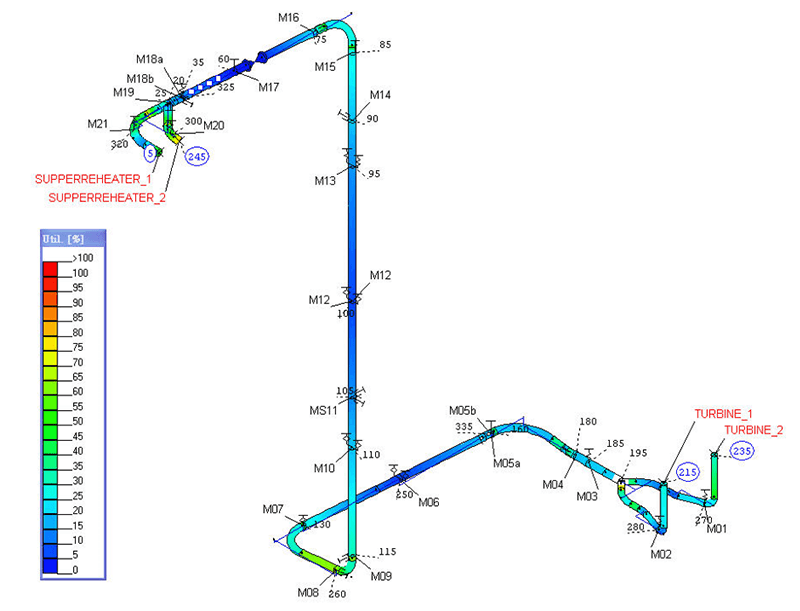

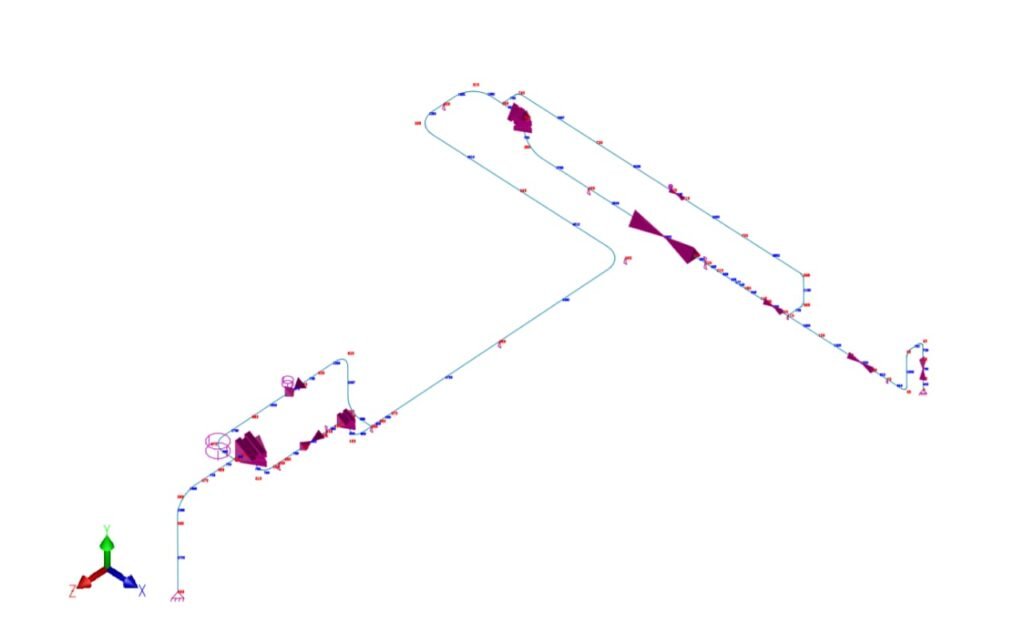

Piping Stress Analysis & Report

Piping stress analysis is a critical process used to evaluate the behavior of pipes and their components under different loads and conditions. This analysis helps ensure that piping systems are safe, reliable, and able to withstand various stresses without failure.

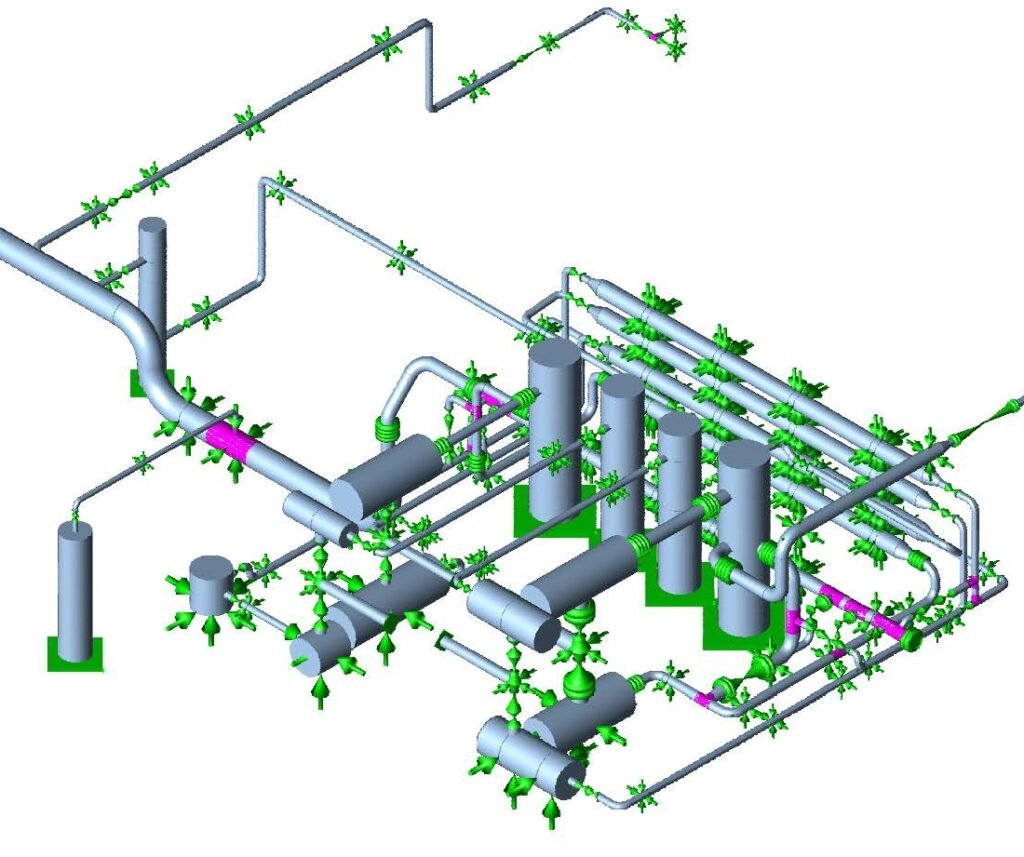

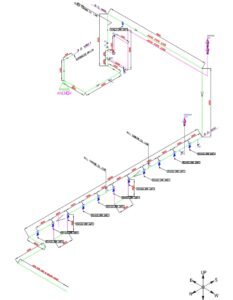

Piping Isometric Drawings

Our services include comprehensive analysis and evaluation of your piping system, identifying potential issues and risks, and recommending appropriate solutions to ensure its integrity and longevity. We also provide detailed reports and documentation to keep you informed and compliant.

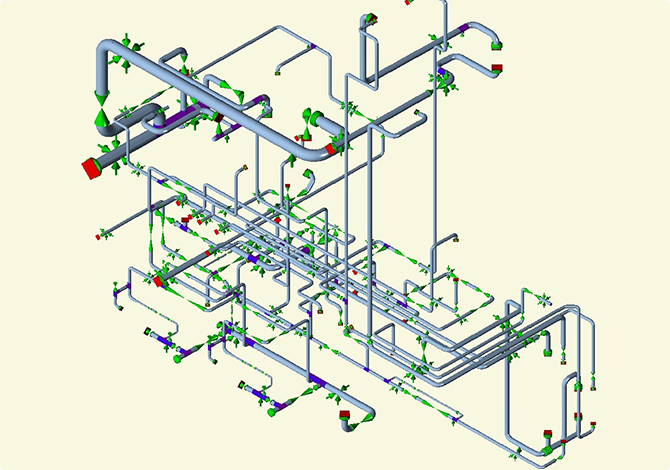

Piping Layout & Reports

When it comes to piping systems, ensuring their strength and safety is crucial. That’s why accurate stress analysis is essential, especially for those that fall under the 𝗔𝗦𝗠𝗘 𝗕𝟯𝟭.𝟭 𝗮𝗻𝗱 𝗕𝟯𝟭.𝟯 𝘀𝘁𝗮𝗻𝗱𝗮𝗿𝗱𝘀.

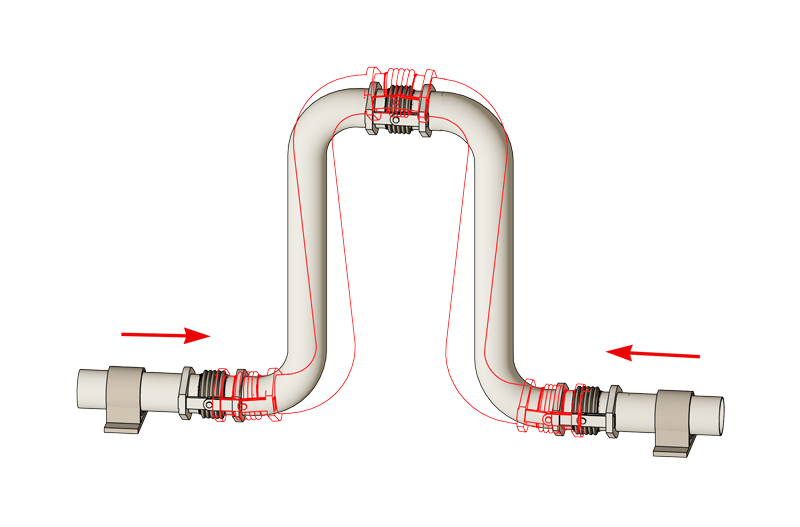

Piping Support & Spring Hanger Report

𝗔𝗦𝗠𝗘 𝗕𝟯𝟭.𝟭 𝗮𝗻𝗱 𝗕𝟯𝟭.𝟯 are two important codes that provide technical guidance for the design, construction, and maintenance of power and process piping systems. They also provide guidelines for the calculation and analysis of stresses and loads on piping systems, as well as the 𝗱𝗲𝘀𝗶𝗴𝗻 𝗼𝗳 𝘀𝘂𝗽𝗽𝗼𝗿𝘁𝘀, 𝗮𝗻𝗰𝗵𝗼𝗿𝘀, 𝗮𝗻𝗱 𝗲𝘅𝗽𝗮𝗻𝘀𝗶𝗼𝗻 𝗷𝗼𝗶𝗻𝘁𝘀.

Project Executed

- Piping Stress Analysis, Design & Engineering of Piping, General Arrangements,

Isometrics, Piping Supports, and Bill of Materials for different prestigious Projects & customers. - High-Pressure Piping, Design, Engineering & Stress Analysis for Pressure from 32 kg/sqcm to 165 Kg/sqcm, Temperature 321 °C to 550 °C.

- Steam Turbine Parallelity & Commissioning.

- More than 100+ projects done for SS engineers, Pune, Hitech, Baramati, Venus fabricators, Walchandnagar, Gupte engineers, Pune, Narmada sugars, Gujrat, Santlal industries, Manipuri, u.p, Adinath SSK, Karmala, Maharashtra, thermotech, Delhi, Walchandnagar industries ltd, India glycol ltd., Satyam power projects pvt. ltd, Ugar sugars, Sadashiv sugars, transmara sugars Kenya, ilfs MSW plant at Gazipur, Pwani oil Mills Kenya, Olam Agro republic of Cango etc

- Steam Piping Vibrations Problem Solving with Turbine Commissioning for KIBOS SUGARS & ALLIED INDUSTRIES LTD., Kenya, Satyam Power Projects Pvt. Ltd.

- Modification of Dumping Grate Boiler Furnace and superheater for Performance achievement & improvement of Combustion Efficiency for Balrampur Chinni Mills Ltd., Balrampur.

- Superheater Modifications to achieve superheater Outlet Temperature from 450 Deg C to 510 Deg C for Dhampur Sugars Ltd. A/C Yamuna Engineering Works.

- NTPC Condition Assessment of Critical Hangers and Stress Analysis of Power Cycle Piping of two units of Boiler at NTPC-TSTPS. NTPC Kaniha, Orrisa , Superthermal 500 MW Power Plant. Unit No 1 & 2.

Case Study

At its core, 𝗽𝗶𝗽𝗶𝗻𝗴 𝘀𝘁𝗿𝗲𝘀𝘀 𝗮𝗻𝗮𝗹𝘆𝘀𝗶𝘀 is the process of determining how much stress a pipe will experience in different scenarios, such as changes in temperature, pressure, or the weight of the fluid flowing through it.

In addition to the design and construction requirements, the ASME B31.1 and B31.3 standards require piping systems to undergo periodic inspections and testing.

At the Inlet line of 15MW turbine parallelity with 0.2mm was achieved. The line had to be set free and restrained where required. Successful commission of the co-gen plant was done.

Top support spring hanger and design for smooth, vibration-free operation steam line.

Why Choose SVR Engineers?

- Unmatched Expertise: Our team brings a wealth of experience to the table, backed by a track record of successful projects across various industries.

- Client-Centric Approach: Your vision is our priority. We listen, understand, and collaborate closely to ensure your goals are met with precision and creativity.

- Innovative Solutions: SVR Engineers embraces cutting-edge technologies and sustainable practices, staying at the forefront of industry trends to offer forward-thinking solutions.

- Comprehensive Services: Whether it’s designing intricate structures, optimizing mechanical systems, or providing expert consultancy, SVR Engineers is your comprehensive engineering partner.

- Timely Delivery: We understand the importance of deadlines. Our efficient processes and dedicated team ensure projects are completed on time, without compromising quality.