Piping Engineer: A Comprehensive Overview From Design to Execution

In mechanical engineering piping engineers deal with industrial designing, analysing, and maintaining proper piping systems. These systems are essential in industries like oil and gas, power generation, and more. The role of a piping engineer extends from conceptual design through detailed engineering and into construction and commissioning phases of industrial projects. In this article, we will explore the scope of a piping engineer, with a focus on the technical aspects, key responsibilities, relevant codes like ASME B31.1 and B31.3, and the importance of piping stress analysis.

Scope of a Piping Engineer

He/She must ensure that industrial piping systems are designed keeping safety, efficiency, and meet industry standards. The scope of their work includes:

1. Design of Piping Systems: Developing layouts and designs for piping systems that transport fluids such as gases, steam, or liquids in an industrial facility.

2. Material Selection: Choosing appropriate materials based on the fluid characteristics, temperature, pressure, and environmental conditions.

3. Piping Stress Analysis: Performing analysis to ensure the system can withstand operational stresses, thermal expansion, and mechanical loads.

4. Compliance with Codes and Standards: Ensuring that all designs and installations comply with industry standards such as ASME B31.1 (Power Piping) and ASME B31.3 (Process Piping).

5. Collaboration with Other Disciplines: Coordinating with civil, structural, mechanical, and electrical engineers to ensure seamless integration of the piping system with other components of the plant.

ASME B31.1 and B31.3: The Key Codes in Piping Engineering

Industrial piping systems must follow specific codes and standards to ensure they are safe, reliable, and perform well. Two of the most critical codes in this regard are ASME B31.1 and ASME B31.3.

ASME B31.1 (Power Piping)

It covers aspects such as materials, design, fabrication, erection, and testing. Compliance with these codes is a critical responsibility of the piping engineer, as it ensures the safe and efficient operation of the system under normal and extreme conditions.

ASME B31.3 (Process Piping)

This code is used for piping in chemical plants, refineries, pharmaceutical plants, and other facilities involved in the handling of chemicals, gases, or other fluids. It emphasises the need for flexibility, corrosion resistance, and material compatibility.

Key Responsibilities of a Piping Engineer

1. Piping Design

A piping design engineer creates detailed layouts and specifications for piping systems. This involves understanding the physical and chemical properties of the fluids being transported and ensuring that the piping system is optimised for flow efficiency, pressure loss, and safety. Some important factors in piping design include:

Pipe Routing

Determining the best paths for pipes to minimise pressure drops and avoid interference with other equipment.

Valves and Fittings

Selecting appropriate valves and fittings for controlling flow, pressure, and temperature.

Support and Anchoring Systems

Designing supports to prevent undue stress on the piping due to weight, vibration, or thermal expansion.

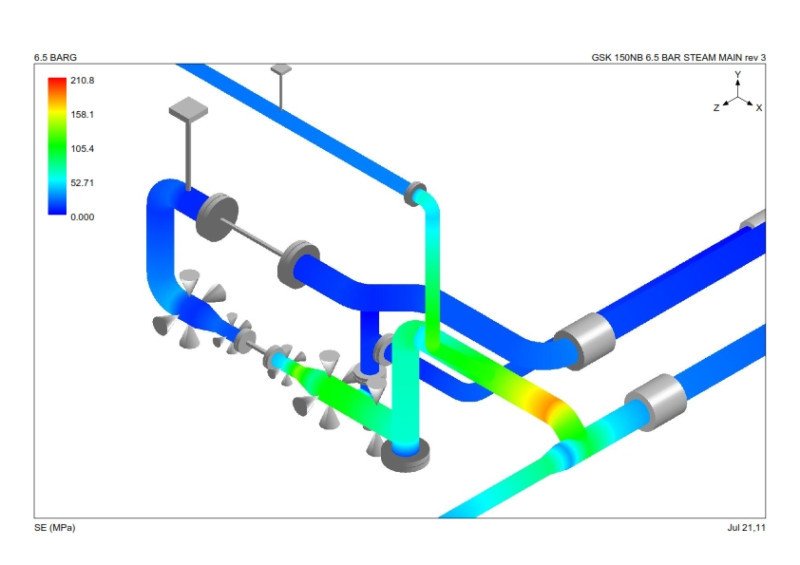

2. Piping Stress Analysis

Piping stress analysis is one of the most critical aspects of piping engineering. This process involves evaluating the stresses and strains on the piping system to ensure that it can withstand operational conditions without failure. To perform piping stress analysis, piping engineers use specialized software such as CAESAR II, which allows for the simulation of different load conditions and provides insights into the system’s safety margins. Various factors are considered, including:

Thermal Expansion

Piping systems often experience temperature changes, leading to expansion and contraction. Engineers must design systems that can absorb this movement without excessive stress on the joints or supports.

Vibration Analysis

High-pressure systems and rotating equipment can induce vibrations in the piping, which must be analysed and mitigated to prevent fatigue failure.

Load Calculations

A piping stress analysis involves calculating the loads imposed by the weight of the pipe, the internal pressure, and external forces such as wind or seismic events.

3. Material Selection and Specification

Material selection is the responsibility of the piping engineer. The choice depends on several factors, including the type of fluid, operating temperature, pressure, and corrosiveness. The correct specification of materials ensures that the piping system can handle the service conditions without degradation, leaks, or failures. For instance:

– Carbon Steel: Often used for high-pressure systems and applications involving steam.

– Stainless Steel: Suitable for corrosive environments or high-temperature applications.

– Plastic Pipes (e.g., PVC or HDPE): Often used for low-pressure and non-corrosive fluid applications.

4. Piping Layout and Optimization

Piping engineers are responsible for developing optimised piping layouts that not only ensure functional operation but also reduce the overall cost and complexity of the system. This includes:

– Minimising Pipe Lengths: Reducing the length of pipes helps decrease material costs and energy losses.

– Avoiding Interferences: The layout should prevent clashes with other equipment or structures in the plant.

– Accessibility for Maintenance: Engineers ensure that valves, flanges, and other components are accessible for maintenance without excessive downtime.

5. Meeting safety and environmental regulations is essential in piping engineering.

A piping engineer must ensure that the system complies with both safety regulations and environmental laws. This includes adhering to standards like ASME B31.1 and B31.3 for mechanical safety and ensuring that hazardous materials are handled in a manner that does not endanger plant personnel or the environment.

Specializations in Piping Engineering

1. Piping Design Engineer

A piping design engineer focuses on the initial phase of a project, where the layout and flow requirements are determined. They use software tools like AutoCAD, PDMS, or SmartPlant 3D to create detailed 3D models and isometrics for construction.

2. Piping Stress Engineer

He/She must specialise in analysing and reporting the stresses imposed on a piping system during its operation. This role involves detailed analysis using software tools to simulate different load conditions, ensure compliance with stress limits, and prevent failures due to factors like thermal expansion or seismic loads.

3. Lead Piping Engineer

A lead piping engineer oversees all aspects of piping engineering for a project, from design to installation. They are responsible for coordinating teams, ensuring adherence to timelines, and maintaining compliance with project specifications and industry codes.

4. Piping Engineering Consultant

A piping engineering consultant provides expert advice and technical support to organisations that need specialised expertise in piping systems. This role involves reviewing designs, conducting feasibility studies, and troubleshooting issues in existing systems.

5. Freelance Piping Engineer

A freelance piping engineer offers flexibility to work on multiple projects for different clients. This role is gaining popularity with the rise of remote work and project-based engagements. Freelancers often provide services like piping design, stress analysis, and consultation on specific aspects of industrial piping systems.

Industrial Applications of Piping Engineering

1. Oil and Gas Industry

Piping systems in the oil and gas industry are critical for the transportation of crude oil, natural gas, and refined products. These systems are subject to high pressures and temperatures, making compliance with ASME codes essential for safety.

2. Power Plants

In power generation plants, piping systems transport steam and water between boilers, turbines, and condensers. Piping engineers must ensure that these systems can handle high temperatures and pressures without experiencing failures.

3. Chemical and Petrochemical Plants

Piping systems in chemical plants are used to transport various chemicals, often under corrosive conditions. Material selection and corrosion resistance are key considerations in these environments.

Conclusion

A piping engineer plays a critical role in the design, analysis, and maintenance of piping systems across industries. From ensuring compliance with industry standards like ASME B31.1 and B31.3 to conducting detailed piping stress analysis, the technical expertise required in this field is extensive. Whether working as a piping engineering consultant, a freelance piping engineer, or a lead piping engineer, professionals in this field are essential for the safe and efficient operation of industrial plants. As industries continue to evolve, the demand for skilled piping engineers remains robust, offering numerous opportunities for specialisation and growth in the field of industrial piping engineering.